Wastewater treatment technology

Advanced Oxidation Processes (AOPs) technology.

Using the Advanced Oxidation Processes (AOPs) likely ozone / UV / H2O2 / composite metal catalyst to decades dissolved organic pollutants in wastewater. In AOPs technology, ozone is added to the contaminated water and is activated by the catalyst or UV or H2O2 to form secondary oxidizing species likely hydroxyl radicals. These strong oxidizing free radicals can oxidize the organic pollutants to be CO2 (mineralization) and removal TOC. Our group focus in planning , design and construction for AOPs. We will promote AOPs in application of water reclamation and raise the biodegradability for refractory organic wastewater.

Bio-sludge conditioning reduction technology

Using high-frequency ultrasound to break up biological cells and increase the hydrolysis rate, biological sludge can be converted into a carbon source for microbial growth, thereby achieving the benefit of sludge reduction.

High, medium and low concentration ammonia removal technology

Gaseous ammonia is formed under the condition of high pH by using ammonia, and the ammonia is separated and formed into ammonium sulfate with sulfuric acid by using a super gravity device and a gas-permeable (MD) membrane, which can be reused later. In addition, the use of O3 + catalysts can convert low-concentration ammonia to N2, further replacing biological treatment technology and effectively solving space problems.

Boron wastewater treatment technology

Using chemical coagulation sedimentation combined with fiber adsorption composite technology, boron in the water is formed into sludge, and the system is introduced into an automatic regeneration program, which enables continuous processing and reaches the discharge standard.

Nitrate nitrogen wastewater treatment technology

Based on the volume and quality of wastewater, a biological treatment system can be established to treat nitrate nitrogen by anaerobic denitrification or distillation to form sludge and salt output.

Chemical treatment technology for inorganic wastewater

Using composite chemical precipitation treatment system to remove fluoride, arsenic, nickel, cadmium and other heavy metals in inorganic wastewater. We also apply the fluidized bed crystallizer system(FBC), membrane system, ion exchange system and other special techniques to solve the problem of high strict effluent standard.

Biological treatment technology

Using porous ceramics bioreactor (PCBR), membrane bioreactor (MBR), upflow anaerobic sludge blanket (UASB) reactor and various biological treatment techniques with aerobic and anaerobic condition. It can achieve to remove organics, ammonia, nitrates and phosphates and other pollutants in wastewater.

High-gravity ammonia removal technology

Small footprint, high removal efficiency, easy operation and maintenance. The technology to increase the centrifugal force and increase the removal capacity can handle a wide range of ammonia nitrogen concentration in wastewater, high removal efficiency, small equipment land and high demand, low requirements for wastewater impurities, suitable for pretreatment of high concentration ammonia nitrogen wastewater, which can greatly reduce the back-end system Load of ammonia nitrogen.

.png)

.png)

Recycled water treatment technology

Tetramethyl ammonium hydroxide (TMAH) recycling technology

We develops the water reclaim technology for the wastewater of general acid/alkaline, local scrubber and so on to agree the water quality of factory's primary and secondary water.In addition, Ammonia & Tetramethyl ammonium hydroxide (TMAH) recycling technology will be applied to reuse chemicals.

UF + RO wastewater recycling technology

The use of UF + RO system, in conjunction with the process quality evaluation of recycled water, purification and reuse of reusable water sources for the process end, on the one hand, it can reduce wastewater treatment operation costs and sewage management costs, and on the other hand, it can also reduce tap water costs and further improve the whole plant recovery rate.

MBR + RO biological wastewater recycling technology

After biological treatment of organic wastewater, the use of UF-grade MBR membrane filtration technology to make its water quality can be recycled with the RO system to achieve the goal of waste water reduction.

.png)

.png)

Pure water treatment technology

Ultrapure water system

Using pretreatment + TWO PSS RO + EDI + UV / TOV + polisher + absolute filter and other technology combinations, and writing PLC + HMI can be fully automated operation, this method can greatly reduce personnel operation and regeneration wastewater problems, and can also purified raw water Ultra-pure water to 18MΩ or more, for field use.

Two-stage RO pure water system

Using pre-processing + TWO PSS RO technology combination, and writing PLC + HMI can be fully automated operation can be purified raw water to ≦ 5uS / cm pure water for supply to the site.

2B3T pure water system

Using resin tower (yang tower, degassing tower and Yin tower) technology combination, combined with PLC + HMI can be fully automatic operation control, purified tap water to more than 2MΩ pure water for the line process end use.

.png)

.png)

Circular Economy

Photoresist and polyimide (PI) recycling equipment

This technology has been widely used in a well-known photoelectric TFT-LCD color filters (Color Filer), TFT, CELL PI process. The research team focused on the photoresist composition and its chemical properties analysis by using the company's patent. The composition and chemical properties of recycling liquid photoresist is same to the original photoresists.

Ammonium sulfate crystal drying equipment

Ammonia nitrogen wastewater, which is common in semiconductor factories, is removed by thin film and other methods, and then sulfuric acid is used for adsorption. The ammonium sulfate recovery liquid is formed, and it is formed into ammonium sulfate crystals through the chemical crystal drying technology, so as to reduce the waste recovery and reuse in the plant.

Precious metal recycling equipment

If the process wastewater contains valuable metals, such as gold, palladium, copper, nickel, etc., the system design will design electrolysis or resin adsorption methods based on water quality concentration and characteristics to recover valuable metals in water. The principle of electrolysis is that waste water passes through an electrolyzer to reduce and recover positively charged metal ions at the cathode; the principle of adsorption is to use a chelating resin to remove specific metal ions in water, then regenerate after saturation, and recover highly concentrated valuable metal ions in the regeneration liquid.

Equipment for converting cryolite from waste hydrofluoric acid

The three major domestic technology industries, semiconductors, liquid crystal display panels, and solar cells, generate a large amount of waste hydrofluoric acid. ReTech develops a system module equipment that can efficiently treat high-concentration hydrogen fluoride waste liquid on the site, and specifically produces high-quality cryolite crystals, to recover the fluorine element and fundamentally solve the problem possible environmental risks and environmental protection problems caused by cleaning and disposal, avoiding the factory to mix the hydrogen fluoride waste liquid into the wastewater treatment plant, effectively increasing the amount of water available for water recycling in the entire plant and reducing the treatment cost of subsequent water recycling .

.png)

.png)

Urban Mining

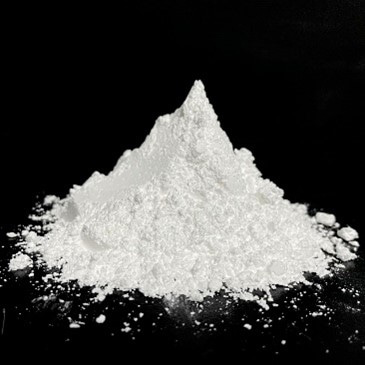

(Na3AIF6)

- Descriptions:

- Synthetic cryolite is an odorless white crystalline powder. The solubility is greater than natural cryolite. Apparent Density<1.0 g/cm3, Hardness 2~3, melting point 1009℃. It's easy to absorb water and become damp.

- Features:

- ReTech cryolite have advantages of consistent particle size, high quality and high purity.

- Applications:

- 1) As a flux in the electrolytic production of aluminum.

2) A wear-resistant additives for abrasive products.

3) A wear-resistant filler for resin and rubber-bonded abrasive wheels.

4) Ferroalloy boiling steel electrolyte, metal flux, casting deoxidizer.

5) Emulsifier for enamel, opalizer for glass anti-reflective coating, flux for soldering materials.

Specifications

| Chemical Composition(%) | Physical Properties | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Test Item | Na3 Al F6 | F | AI | Na | SiO2 | Fe2O3 | SO42- | CaO | P2O5 | H2O | Ignition Loss |

| Limits | 96~99% | 53%/min | 13%/min | 32%/max | 0.36%/max | 0.08%/max | 0.8%/max | 0.6%/max | 0.03%/max | 0.4%/max | 2.5%/max |

Zinc Sulfate

(ZnSO4 . 7H2O)

- Descriptions:

- Colorless crystals, small acicular or granular crystalline powder, odorless, astringent, metallic smell, weathering in air.

The solution is acidic to litmus, the specific gravity is 1.957 (25/4°C), and the melting point is 100°C. - Lose 7H2O at 280°C, soluble in water and glycerin, insoluble in alcohol, low toxicity.

- Applications:

- 1) As the artificial silk

2) For food

3) For feeds

4) As mordant

5) As wood preservative

6) As analyze reagent

Specifications

| Chemical Composition(%) | |||||||

|---|---|---|---|---|---|---|---|

| Test Item | Zinc(Zn) | Arsenic(As) | Lead (Pb) | Cadmium(Cd) | Mercury(Hg) | Insoluble (in water) | pH |

| Limits | ≥21.00 % | 5 ppm Max | 20 ppm Max | 20 ppm Max | 5 ppm Max | ≤ 0.02% | ≥ 3.0 |

| Remark | 50g/L aqueous solution |

||||||

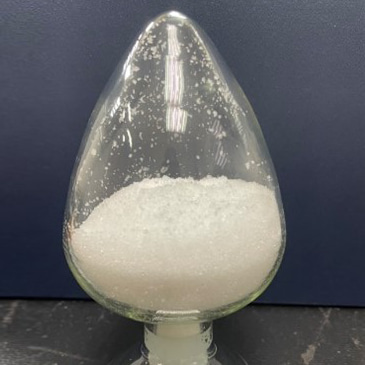

Ammonium Sulfate

(NH4)2SO4

- Descriptions:

- white or slightly yellow crystal

- Features:

- 99% crystal

- Applications:

- 1) As flux

2) For leather using

3) As plating solution

4) Dyeing and finishing

5) As the material of ammonium persulphate

Specifications

| Chemical Composition(%) | |||||||

|---|---|---|---|---|---|---|---|

| Test Item | concentration | Sulphur Content | H2O | H2SO4₄ | |||

| Limits | ≥ 99 % | ≥ 24 % | < 0.3 % | < 0.1 % | |||

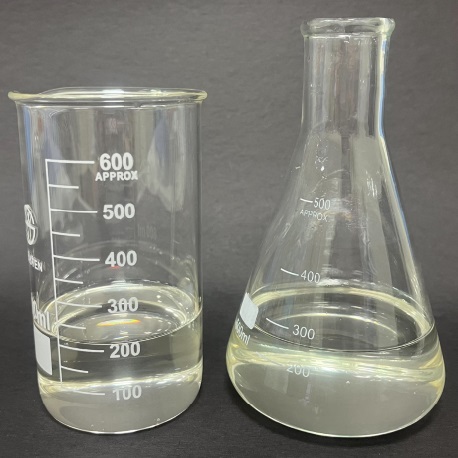

Sodium Aluminate

(NaAlO2)

- Descriptions:

- White Liquid

- Applications:

- 1) As mordant

2) As mesolite

3) As purified water

4) As soaps and cleaning compounds

5) As concrete accelerator - Specifications:

- Customized according to customer needs

Contact person: Jenny

E-mail account: jenny_wang@retech.com.tw

Phone number: +886-4-24628828 #308